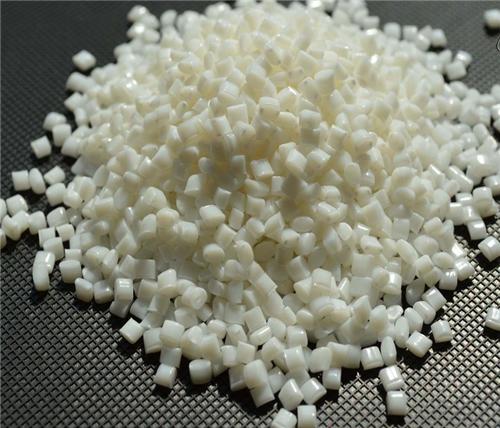

Five general plastics of Jiangmen engineering plastics

The five internationally used engineering plastics are polyamide (PA), polycarbonate (PC), Polyoxymethylene (POM), polyphenylene oxide (PPO) and thermoplastic polyester (PBT) Engineering plastics can be divided into general engineering plastics and special engineering plastics.

The former mainly includes polyamide, polycarbonate, polyformaldehyde, modified polyphenylene oxide and thermoplastic polyester; The latter mainly refers to engineering plastics with heat resistance above 150 ℃. The main types include polyimide, polyphenylene sulfide, polysulfone, aromatic polyamide, polyarylate, polyphenylene ester, polyarylether ketone, liquid crystal polymer and fluororesin.

1 polyamide (PA)

Advantages: low specific gravity, high tensile strength, wear resistance, good self lubrication, excellent impact resistance, with both rigid and flexible functions, its processing is simple, high efficiency and light specific gravity.

Defects: lack of filling, dull appearance, easy to change color, large heat shrinkage, rapid cooling of products, poor exhaust, difficult demoulding, difficult blanking, etc.

Primary use: processed into various products to replace metal, widely used in cars and transportation industry. Typical products include pump impeller, electric fan blade, valve seat, bushing, bearing, various external plates, car electrical appearance, cold and hot air control valve and other parts.

2 polycarbonate (PC)

Advantages: it not only has the strength similar to non-ferrous metals, but also has ductility and strong endurance. Its impact strength can not be damaged by hammering, and can fully appreciate the explosion of TV screen. The transparency of polycarbonate, and can apply any coloring.

Defects: silver wires, bubbles, discoloration of resin, decrease in clarity, possible weld marks, easy cracking of products, difficult demoulding, etc.

Primary use: it is widely used in various lampshades, signal lights, bright protective panels of gymnasiums and stadiums, daylighting glass, glass of high-rise buildings, car mirrors, windshield panels, aircraft cabin glass, and motorcycle driving. Shopping malls are computers, office equipment, cars, alternative glass and sheets. CD and DVD discs are one of the potential shopping malls.

3 Polyoxymethylene (POM)

Advantages: it has the hardness, strength and rigidity of similar metals. It has good self lubrication, excellent fatigue resistance and elasticity in a wide range of temperature and humidity. In addition, it has good chemical resistance and low cost.

Defects: poor thermal stability and thermal oxygen stability, etc.

Primary use: widely used in electronic and electrical, machinery, appearance, daily light industry, cars, building materials, agriculture and other fields. POM also shows a good growth trend in many new fields, such as medical technology, sports equipment and so on.

4 polyphenylene oxide (PPO)

Advantages: it has the function of induction. It is characterized by dimensional stability and excellent electrical insulation under long-term load. It can be used for a long time at -127 ~ 121 ℃. With water and steam resistance, the product has high tensile strength, impact strength and creep resistance. In addition, it has good wear resistance and electrical function.

Defects: poor melting fluidity, difficult processing and forming, poor light resistance, discoloration when used in the sun for a long time, poor resistance to inorganic acid, alkali, aromatic hydrocarbon, halogenated hydrocarbon, oil and other functions, easy swelling or stress cracking, etc.

Primary use: mainly used to replace stainless steel in manufacturing surgical and medical instruments. In the electromechanical industry, it can be used to manufacture gears, blower blades, pipes, valves, screws and other fasteners and connectors. It is also used to manufacture components in the electronic and electrical industries, such as coil frames and printed circuit boards.

5 thermoplastic polyester (PBT)

Advantages: good processing and electrical functions, low glass transition temperature of PBT, rapid crystallization at mold temperature of 50 ℃, and short processing cycle.

Defect: not easy to get.

Primary use: widely used in electronic, electrical and car industries. Due to its high insulation and temperature resistance, PBT can be used as flyback transformer of TV, distributor and ignition coil of car, shell and base of office equipment, various external parts of car, electromechanical fan of air conditioner, base of electronic stove and shell of office equipment.

Source: Jiangmen engineering plastics http://xrtsm.com.cn/

-

04-13

PVC Engineering Plastics: how PVC plastic pipes are formed

The forming process of PVC plastic pipes should start from the raw materials of PVC plastic granules, which can be divided into soft PVC and hard PVC according to the added amount of stabilizer, plast

-

11-12

What is the filling property of Jiangmen engineering plastics

What is the filling property of Jiangmen engineering plasticsIn recent years, PC modified plastics have developed rapidly in China, and its industrial system is gradually established and improved. Th

-

10-08

Jiangmen Engineering Plastics: how to classify Jiangmen engineering plastics?

How to classify Jiangmen engineering plastics? 1. Classification by application characteristicsAccording to the different application characteristics of famous plastics, plastics are usually divided

-

08-30

Application scope of PBT engineering plastics

PBT engineering plastics are widely used in electronics, car industry, office machinery and other fields. In Japan and the developed countries in Europe, PBT engineering plastics are mainly used in t