Halogen free flame retardant for engineering plastics is one of the hot spots

For flame retardant materials, halogen-free flame retardants for engineering plastics have become a hot topic in the recent development because of the requirements of environmental protection certification of some large multinational companies in the European Union and abroad.

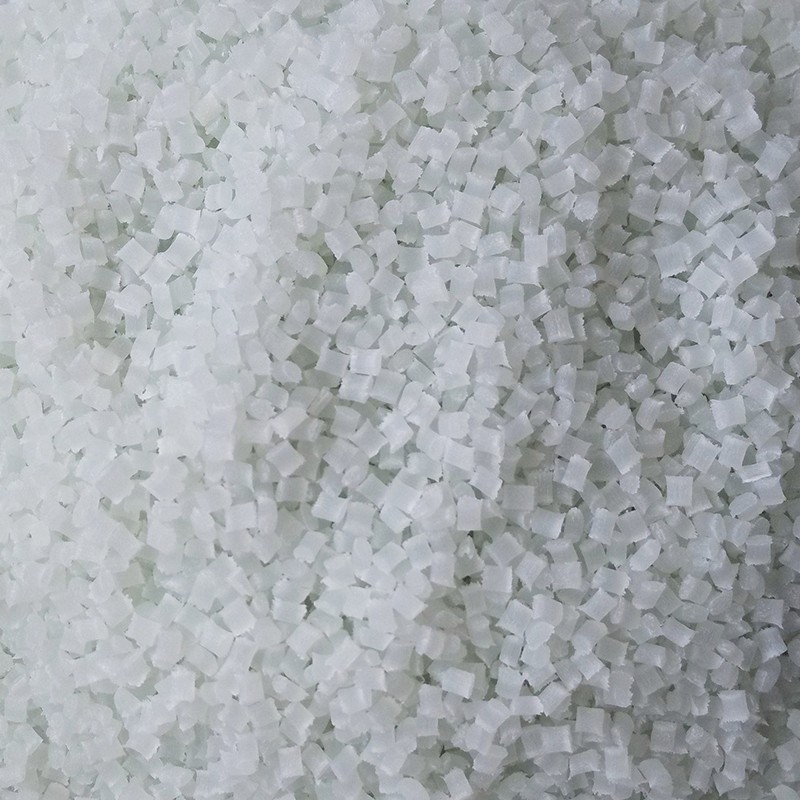

At present, some domestic companies have copied the op series products (such as op-1240, op-1312) of Clariant, Germany for halogen-free flame retardants used in PA, PBT, pet and other engineering plastics. In contrast, the cost advantage of similar products of domestic suppliers is obvious. However, because the synthesis process still needs to be further improved and the products still have the problem of heat resistance and instability, domestic modified plastic factories are often cautious in selecting domestic substitute products. Imported flame retardants are still used for products with high requirements and good prices, while domestic substitutes are used for products with low requirements and low prices. This point will be changed with the improvement of domestic products.

The market demand for halogen-free flame retardants for TPE has increased significantly recently, but EBs and oil in the composition of TPE are not conducive to flame retardance, and the product application is mostly due to wire products (appearance parts). People have strict requirements for such additives. Now, they mainly focus on: high requirements for flame retardancy efficiency (relatively small increase), good precipitation resistance (resistance to hot water extraction above 80 ℃), good processing function (good temperature resistance, stable wire extrusion), Smooth appearance (good compatibility with resin and fine particle size). At present, including Germany Clariant company (op-935/930), Japan Asahi electrochemical company (adk2200s) and domestic psf-110t chemical company (epfr-110t), all basic products can be selected. People often mix some other halogen-free flame retardants on the basis of the above products to reduce costs or improve functions.

This article is from Jiangmen Engineering Plastics:http://xrtsm.com.cn/

-

04-13

PVC Engineering Plastics: how PVC plastic pipes are formed

The forming process of PVC plastic pipes should start from the raw materials of PVC plastic granules, which can be divided into soft PVC and hard PVC according to the added amount of stabilizer, plast

-

11-12

What is the filling property of Jiangmen engineering plastics

What is the filling property of Jiangmen engineering plasticsIn recent years, PC modified plastics have developed rapidly in China, and its industrial system is gradually established and improved. Th

-

10-08

Jiangmen Engineering Plastics: how to classify Jiangmen engineering plastics?

How to classify Jiangmen engineering plastics? 1. Classification by application characteristicsAccording to the different application characteristics of famous plastics, plastics are usually divided

-

08-30

Application scope of PBT engineering plastics

PBT engineering plastics are widely used in electronics, car industry, office machinery and other fields. In Japan and the developed countries in Europe, PBT engineering plastics are mainly used in t